|

Introduction to typical process flow of self-hardening sand production

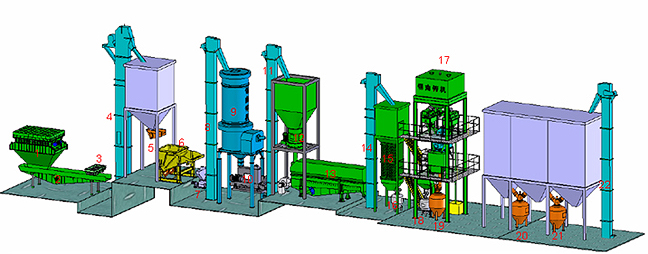

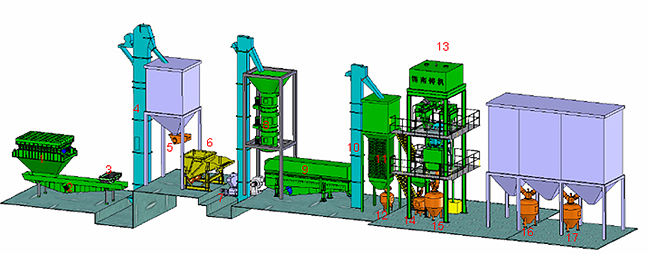

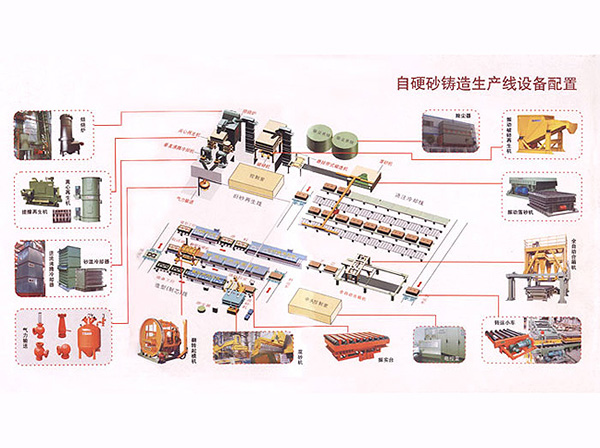

Self-hardening sand production process. According to the layout of the foundry and the production program, develop appropriate plans. It is generally mainly recovered and broken by old sand. regeneration. Go to the ash. Temperature regulation, sand transportation and sand mixing, modeling, core making and other components.

1. Recycling of old sand: The casting and sand are separated by the falling sand machine, and then transported by vibration conveyor or belt conveyor, and the permanent magnet separator is suspended. After the permanent magnet pulley is de-ironed, it is lifted into the sand magazine by the bucket lifter.

2. Old sand crushing regeneration: The aggregate sand in the old sand storage is evenly fed to the crusher through the vibrating feeder, and then in the vibration crusher, roaster, scrub regenerator, centrifugal regenerator, pneumatic impact regenerator Membrane regeneration (depending on process requirements. Regeneration equipment may be preferred). The old sand containing a large amount of fine dust is sent to the reclaimed sand store for storage after being removed by ashing and cooling to meet the process requirements.

3. New and old sand transportation: The new sand can be sent to the new sand storage tank through the bucket lifter or pneumatic conveying, and then sent to the upper bucket above the sand mixer by pneumatic conveying. The old sand can be sent by pneumatic conveying to the hopper above the sand mixer or mixed with the new sand ratio

After being sent to the top of the sand mixer.

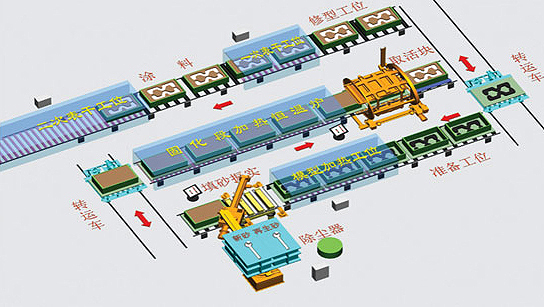

4, modeling. Core: new. The old sand is mixed into the sand box or the core box by the self-hardening sand mixer according to the process requirements, and is hardened and demoulded. After repairing, coating, and drying, move to the boxing section. After casting, it is cooled to the temperature specified in the process.

|

Haitai ReGong Industry

Haitai ReGong Industry Search The Product

Search The Product Product

Product